Set-up, measurement, accuracy, test method, result; Words that test engineers know and live by. We all want accurate results and if you ask 10 test engineers, you might get 10 different answers on how to get there. When you tell a test engineer that his or her results are incorrect, they may take offense and push back and say they’re ones that are correct and its your products that are out of specification.

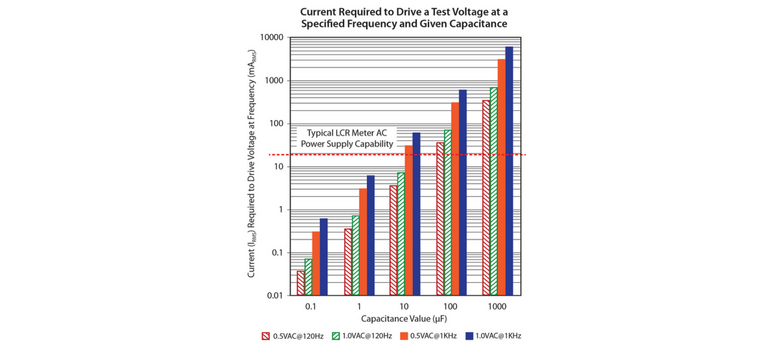

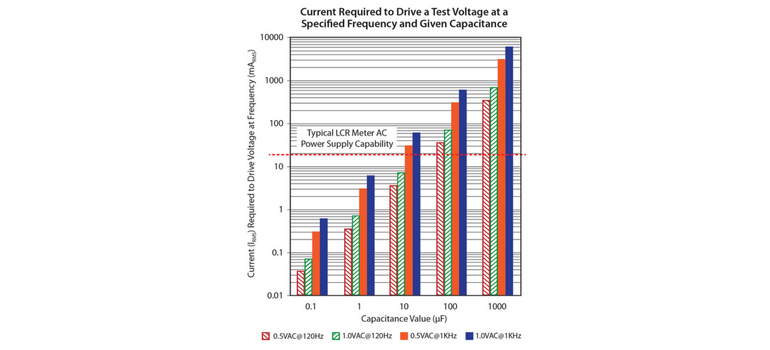

This is what we find when encountering measurement or correlation issues when endeavoring to measure high value (typically considered to be > 1uF) Multi-Layer Capacitors or MLCC’s. The inability to accurately measure high value MLCC’s has been an issue in our industry for years with the advent of high value MLCC’s, the issue does not appear to be going away anytime soon. This is due to the fact that many capacitance testers and LCR meters used throughout the industry are not designed to, nor have the capability to correctly measure capacitance of high capacitance (Hi-Cap) MLCCs. This is the case whether we are measuring capacitors at 1 VAC and 1 KHz or 0.5 VAC and 120 Hz. The inability to correctly measure high capacitance MLCCs is due to two reasons. First, many LCR meters do not have the capability of supplying enough current to the capacitor being tested at 1KHz and 1 VAC, resulting in a reduced measurement voltage which results in an artificially reduced capacitance reading. Second, Hi-Cap MLCCs typically utilize Class 2 dielectrics (e.g. X5R, X6S, X7R, X7S, etc.) that are sensitive to test voltage in the sense that changing test voltage results in change in capacitance. Since Class 2 dielectrics are typically made with ferroelectric dielectric materials that are non-linear in behavior with respect to test voltage, this change in capacitance will occur. These two reasons plus the ageing phenomenon (discussed in an upcoming Blog) exacerbates the issue and explains why it is essential to ensure that you apply the correct test voltage to the MLCC when measuring or testing a capacitor and trying to obtain its actual capacitance value. Incorporating the right bridge and applying the correct parameters is essential in obtaining an accurate capacitance measurement.

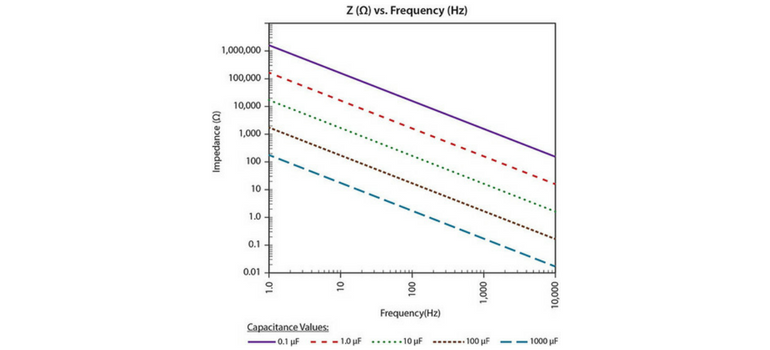

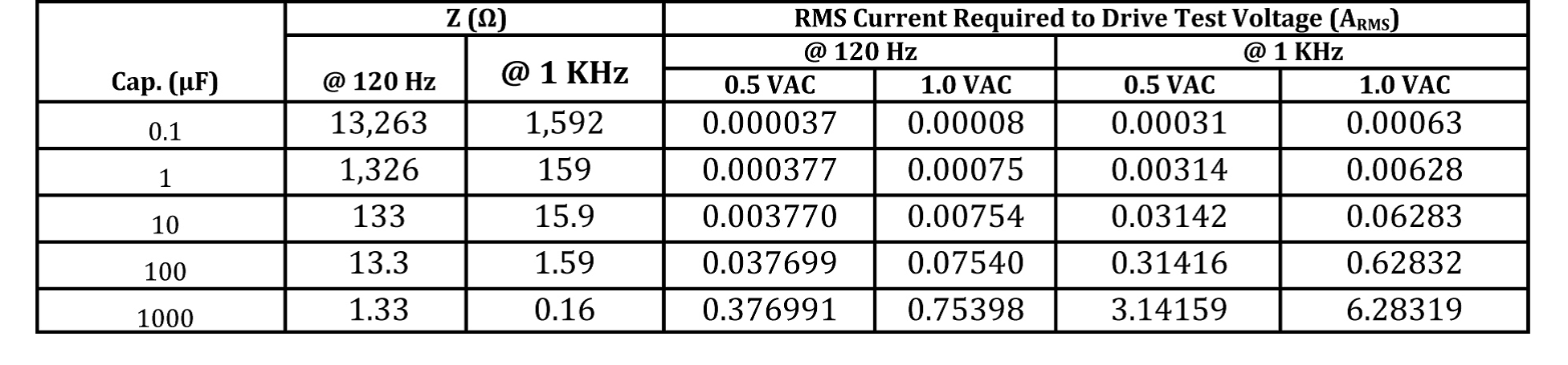

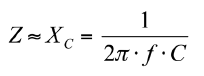

To ensure that capacitance is correctly measured, each capacitor must be tested under the correct conditions. The correct conditions for measurement depend upon the capability of the measurement equipment as well as the nominal capacitance to be measured. Since Capacitance measurements are typically performed in the low range of the frequency scale around 120Hz-1KHz, the capacitive reactance (XC) typically dominates the impedance equation, and Z may be estimated from the relationship:

From this relationship, it is clear that the impedance of a capacitor is dependent upon frequency and capacitance value. So why does the electronic industry make a standard to measure a 10uF MLCC at 1KHz but a 15uF at 120Hz?

From this relationship, it is clear that the impedance of a capacitor is dependent upon frequency and capacitance value. So why does the electronic industry make a standard to measure a 10uF MLCC at 1KHz but a 15uF at 120Hz?

In my next post I will discuss this in more detail and demonstrate how that works in the form of a graph and some additional data. Then, I will continue with providing information and data to support the theory that MLCC’s with the value of 10uF should also be tested at 120Hz and not 1kHz. This should “stir the pot” a bit as I have encountered numerous instances where this is the case when older test equipment is used throughout the industry. Some customers have re-evaluated their test frequencies based on cap value and the type of test equipment they have and have done so with good success.

Hope to see you next month and as you know – “Engineers make the world go around! ”TM

.png?width=1276&height=1545&name=figure1-post3%20(1).png)

.jpg?width=600&height=587&name=figure1---z-vs-freq-of-mlcc%20(1).jpg)

From this relationship, it is clear that the impedance of a capacitor is dependent upon frequency and capacitance value. So why does the electronic industry make a standard to measure a 10uF MLCC at 1KHz but a 15uF at 120Hz?

From this relationship, it is clear that the impedance of a capacitor is dependent upon frequency and capacitance value. So why does the electronic industry make a standard to measure a 10uF MLCC at 1KHz but a 15uF at 120Hz?