What are Whiskers?

“Whiskers” are protrusions that grow from a metal film over time. They can achieve high aspect ratios, growing to considerable lengths and may result in electrical interconnection of adjacent terminals. This can happen when a whisker grows from one terminal to another, as in the case of fine pitch electronics, or when a whisker grows, then shears from its source and lands between two terminals interconnecting them electrically. While this is rare, it has caused considerable concern in the electronics community.

Sn Whiskers

Tin whiskers are Sn protrusions that grow from a tin film. They may occur on the terminals of chip components such as multilayer ceramic capacitors (MLCCs), chip resistors, chip inductors, varistors, etc. They are observed much less frequently than in the past as Sn finishes have evolved as manufacturers’ knowledge of Sn whiskers and how to avoid them has developed.

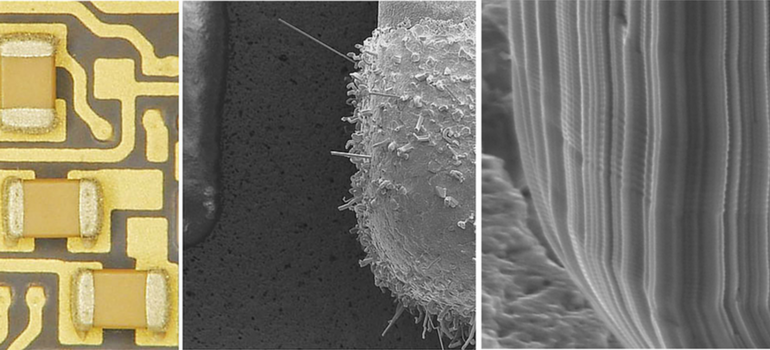

The micrographs above illustrate Sn whiskers at three different magnifications. At lower magnification (left), they may appear as “fuzz” on the surface of the terminations. At increased magnification (center), they may present as high aspect ratio protrusions or “whiskers” that grow over time. At high magnification (right), they typically appear striated on the exterior. Some of the striae may also have horizontal ridges which have been associated with thermal cycling or other episodic events resulting in whisker growth.

How They Form

Formation of Sn whiskers is related to stress (usually compressive stress) within the film from which they propagate. Stress can be caused by several different sources, such as residual stress from the film deposition process (typically electroplating), or from the growth of intermetallic (IMC) phases below the surface of the film as described in a previous post on this blog, or by thermal cycling, or by bending stress in plated leads in the case of leaded components, or the like. These stresses act to extrude the whiskers out from the plated film. Subsequently, much effort has been expended in learning how to reduce or eliminate these film stresses in electroplated Sn films.

Where They Occur

Sn whiskers associated with reflow mounted or wave solder mounted chip components are rare because the stresses formed in the electroplated tin film during the plating process are relieved during the soldering process. They are more common when the mounting technique used does not provide an opportunity for stress relief, such as when mounting with conductive epoxy, and conductive epoxy mounting is mainly where Sn whiskers have been observed in relation to surface mounted chip components.

Sn whiskers have also been observed in unmounted chip components. This was more prevalent in the early days of conversion from Pb/Sn finishes to Sn finishes for RoHS, but is much less frequent in contemporary chip components as manufacturers have developed low stress Sn finishes through the development of low stress tin electroplating chemistries and processes. These electrodeposited film chemistries are typically low in carbon and other impurities, such as Zn, and are “matte” in appearance due to relatively large and uniform Sn grain size (typically ~5 µm on average). With these developments suppliers have been successful in eliminating the incidence of harmful Sn whiskers.

Solutions and Conclusion

Through development of low stress plated Sn finishes, the worry of Sn whiskers has been eliminated with regard to chip components, if you use a supplier who has conquered plated film stress. Sn whiskers will also not likely be an issue if you use a solder reflow process or wave soldering to mount your chip components. If you use conductive epoxy mounting and you still observe Sn whiskers, you may want to heat treat the chip components using a mild heat treatment near the melting point of Sn (~232C). Use of conformal coating on assemblies will also eliminate whisker-related problems. I hope that helps. May you never see another Sn whisker in your assemblies…TTFN! ; )

* Micrographs courtesy of NASA